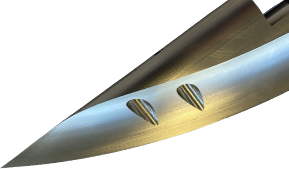

5-Axis Precision Machining

Using the latest 5-axis CNC machining equipment and techniques, our skilled team are able to engineer precision components for high-stress environments and formidable technical challenges.

Whether you need a one-off prototype or higher volume, we work with you from your design right through to delivery to ensure excellent results.

Richard

5-Axis machining specialist

“Our highly experienced team of 5-axis machinists are happy to work with our customers’ bespoke and complex designs to produce repeatable, cost-effective components.”

Examples of our 5-axis work

Sector: Subsea

5-axis Milling & 3D CMM CAD modelling and measurement

Sector: Tooling

5-axis machined, CNC turned &

CNC milled component

Sector: Oil and Gas

5-axis machined component

during CMM measurement

Sector: Subsea

5-axis machining and specific surface finishing

A Selection Of Our 5-Axis Machines

VTC-800/20SR

X 2000 Y 800 Z 720

XYZ UMC 5X

X 600 Y 600 Z 500

Table Ø600

INTEGREX i-300ST

100 Dia 1500 Ctrs

400 Dia 400 Lg

Defining the right materials

Using the right material is crucial to your project’s success. Our team has many years’ experience working with a wide range of materials.

We are experts at working with commonly used alloys, non-ferrous metals and specialist plastics, right through to different exotic alloys and oil-grade materials. We’re always on hand to discuss your requirements.

FAQs

5-axis CNC machining uses computer numerical control (CNC) to move a machined part or a cutting tool along 5 axes at the same time. With the help of computer-aided manufacturing (CAM) software, we ensure synchronised and smooth operations to avoid tool path collisions.

To best understand the 5-axis CNC process, you must first understand how other basic axes machines work.

- A 1-axis machine has a tool that moves up and down on one axis. We refer to the up and down axis as the Z-axis. An excellent example of this movement is the up and down motion of a drill bit.

- 2-axis machines mill items on only the X (side to side) and Y (back and forth) axes.

- A 3-axis machine incorporates the vertical movement (Z-axis), the side to side (X-axis) and back and forth (Y-axis).

- A 2.5-axis machine generally has vertical functionality but will not move along the Z-axis when the X and Y axes are moving.

- 5-axis machines incorporate all the linear motion capabilities of the machines mentioned above but also have an additional two axes to allow rotary motion. This rotary motion is on the A and B axes. Movement across the axes allows the cutting tool to access the machined object from all directions. The overall benefit of this machine is efficiency and flexibility as everything can be done in one process with fewer set-ups.

Increased productivity

5-axis milling means very complicated parts can be machined quickly. This high-precision process can normally mill large parts by using one set-up. This increases productivity and reduces lead times for a faster turnaround.

Unrivalled accuracy & precision

Compared to machines with fewer axes, 5-axis milling has an unrivalled level of accuracy. With the help of CNC, this milling process delivers incredibly precise results; particularly helpful when an extra high-quality result is needed.

Versatility

Both the table and the cutting tool can be tilted and adjusted to have a constant chip load and to maintain the best cutting position.

Trusted by

Looking for more information?

To discuss your project or to get a quote, please contact one of our experts below. Or alternatively, you can read one of our comprehensive case studies.

Manufactured in the UK

Manufactured in the UK

Rapid quoting

Rapid quoting

Class leading quality

Class leading quality

Express delivery

Express delivery