CNC Turning

Our well-invested CNC precision turning section has the capability to complete traditional 2 axis CNC turning up to our twin turret, twin spindle machining with live tooling for complex parts.

Whether you need a one-off prototype or higher volume, we work with you from your design through to delivery to ensure excellent results.

Craig

CNC Turning specialist

“Our experienced engineers, many of whom have trained and remained with the company, provide a fast and efficient service utilising our comprehensive CNC turning machines always with a focus of quality and service.”

Examples of our CNC Turning work

Sector: Food Production

CNC turning & CNC milling,

finishing

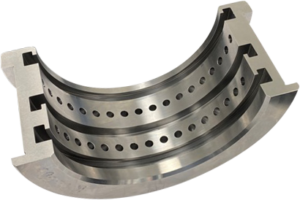

Sector: Defence/Subsea

5 Axis turning and milling,

finishing

Sector: Subsea

CNC turning & CNC milling,

surface treatment

Sector: Defence

CNC turning, 5 Axis milling,

EDM, grinding

A Selection Of Our CNC Turning Machines

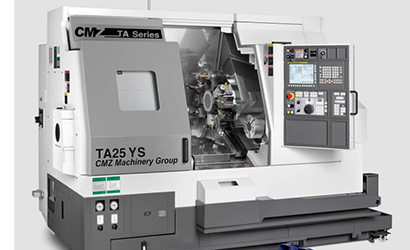

CMZ TA25Y LATHE

300 Dia 640 Ctrs Y 120

CMZ TD35Y

310 Dia 1350 Ctrs Y 120

MAZAK QUICKTURN 350

420 Dia 1230 Ctrs

Defining the right materials

Using the right material is crucial to your project’s success. Our team has many years’ experience working with a wide range of materials.

We are experts at working with commonly used alloys, non-ferrous metals and specialist plastics, right through to different exotic alloys and oil-grade materials. We’re always on hand to discuss your requirements.

FAQs

CNC turning involves a cutting tool operating on a single point inserted parallel to the material being machined. The material turns on the lathe while a cutting tool traverses to make specific cylindrical cuts set with precise measurements.

Installing different tools in the lathe tooling head produces different results, making it easier to produce the parts in single operations. Contours, tapers and cuts can be created in the material’s angles and depths.

The process is automated through the whole machining operation. Speeds can be adjusted to get a high level of accuracy compared to the traditional turning techniques.

High accuracy

CNC turning is computer controlled, an essential feature in production of high-end engineering parts.

High precision

With turning tolerances of up to 0.025 mm, CNC turning is suitable for mass producing highly precise components.

Consistency

A CNC turning system allows for designs to be consistently repeated and manufactured.

Complexity

Most CNC turning machines have a dual spindle and multi-turret setup. This makes it possible to manufacture complex components in just one operation.

Cost effective and fast

Conventional methods would need several turning functions, which are slow and unable to deliver the same level of precision. CNC turning is cost-effective and faster than traditional machining methods, cutting the time it takes to get your product to market.

Trusted by

Looking for more information?

To discuss your project or to get a quote, please contact one of our experts below. Or alternatively, you can read one of our comprehensive case studies.

Manufactured in the UK

Manufactured in the UK

Rapid quoting

Rapid quoting

Class leading quality

Class leading quality

Express delivery

Express delivery