CNC Milling

Our CNC milling processes quickly produce prototypes and precision-engineer final parts to get your project moving.

We work with you from your initial design right through to delivery, ensuring excellent results.

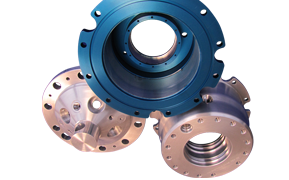

Examples of our Milling work

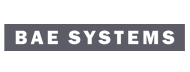

Sector: Subsea

5-axis Milling & 3D CMM CAD modelling and measurement

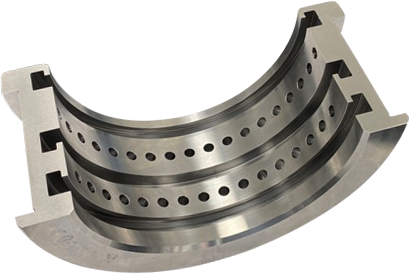

Sector: Tooling

5-axis machined, CNC turned &

CNC milled component

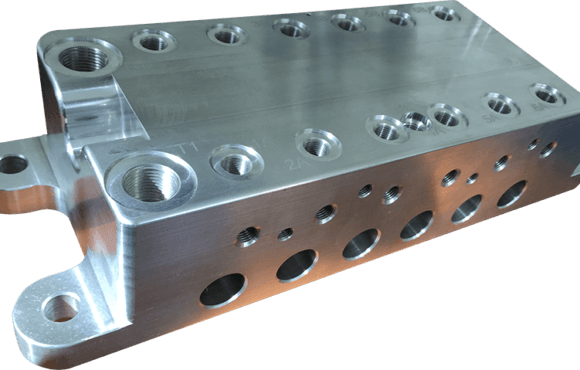

Defence/Subsea

5 Axis turning and milling,

finishing

Sector: Subsea

5-axis machining and specific surface finishing

A Selection Of Our CNC Milling Machines

Mazak Nexus 510c

X 1000 Y 510 Z 510

Deckel Maho DMC 64V

X 600 Y 600 Z 500

Haas VF-5/40 VMC

X 1270 Y 660 Z 635

Defining the right materials

Using the right material is crucial to your project’s success. Our team has many years’ experience working with a wide range of materials.

We are experts at working with commonly used alloys, non-ferrous metals and specialist plastics, right through to different exotic alloys and oil-grade materials. We’re always on hand to discuss your requirements.

FAQs

CNC milling uses computer numerical control (CNC) to remove material to create an end design. CNC milling produces engineered machine parts to the highest levels of precision.

Adaptable

Modern CNC milling machines can perform a wide range of operations, making them more complicated than traditional milling machines.

High-precision machining

CNC machines offer different features such as chamfering, slotting and threading. These different features produce complex designs of high quality within a single CNC milling machine. CNC machines have tolerances of around +/- 0.1 mm, perfect for even the most sensitive parts.

Suitable for a range of materials

CNC milling machines use specific types of materials suitable for producing the parts through the machine’s milling operations. The selection process for the materials is exact. Metals suitable for CNC milling include stainless steel, mild steel, tool steel and aluminium. Suitable plastics include ABS, polycarbonate, PEEK, PTFE, HDPE, POM and nylon.

Trusted by

Looking for more information?

To discuss your project or to get a quote, please contact one of our experts below. Or alternatively, you can read one of our comprehensive case studies.

Manufactured in the UK

Manufactured in the UK

Rapid quoting

Rapid quoting

Class leading quality

Class leading quality

Express delivery

Express delivery