CMM Inspection

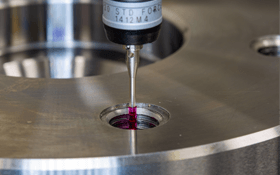

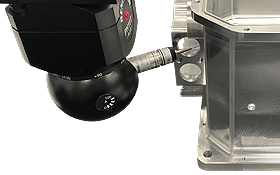

To achieve the highest standards of accuracy and precision, all our finely engineered components are passed through a quality process using a coordinate measuring machine. This ensures that you receive a product that matches your specification and requirements.

James

CMM Inspection specialist

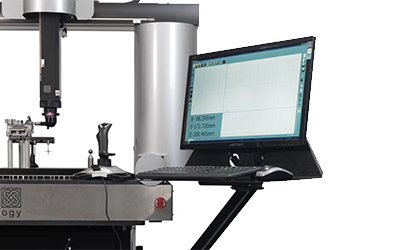

“Our dedicated inspection team operate from a purpose-built, temperature-controlled inspection department. Working with our skilled engineers we act as the customers advocate to ensure that parts are delivered right first time. Whether you require detailed release reports or simple C of C, our quality engineers will ensure that the right documentation is with the goods or emailed in advance for pre-arrival.”

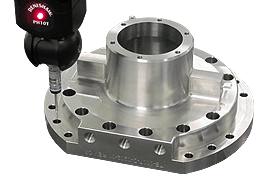

Examples of our CMM Inspection work

Sector: Subsea

Sector: Food production

Sector: Automotive

Sector: Oil & Gas

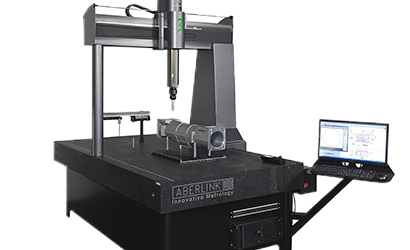

A Selection Of Our CMM Machines

ZENITH TOO 1500 CMM

AXIOM TOO 900 CMM

STARRETT SIGMA HB 400

Defining the right materials

Using the right material is crucial to your project’s success. Our team has many years’ experience working with a wide range of materials.

We are experts at working with commonly used alloys, non-ferrous metals and specialist plastics, right through to different exotic alloys and oil-grade materials. We’re always on hand to discuss your requirements.

FAQs

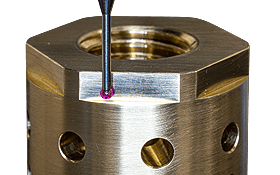

A CMM (coordinate measuring machine) is a tool that accurately measures the geometry of a solid part. It is used for objects and products that need precise inspection and measurement to determine their overall quality. The CMM measures an object’s characteristics and dimensions based on a 3D projection of the shape or the shape itself.

The CMM uses three axes – the Y, Z and X axes – to measure the object to allow for more accurate positioning in other precision machinery.

Coordinate measuring machines are ideal for precisely measuring engineering parts and components.

Profiling

The CMM captures different profile information to provide 2D and 3D dimensions and characteristics of the components.

Depth

The CMM can create a mapped-out outline of an object with up to two stereo images.

Angling

With the CMM, two points of a component can be measured and produce results on orientation and angles.

Dimensioning

The CMM allows users to measure multiple axes of a machine’s component, giving you precise dimensions. Knowing every specific dimension is crucial to avoid potential liabilities in the future.

Trusted by

Looking for more information?

To discuss your project or to get a quote, please contact one of our experts below. Or alternatively, you can read one of our comprehensive case studies.

Manufactured in the UK

Manufactured in the UK

Rapid quoting

Rapid quoting

Class leading quality

Class leading quality

Express delivery

Express delivery